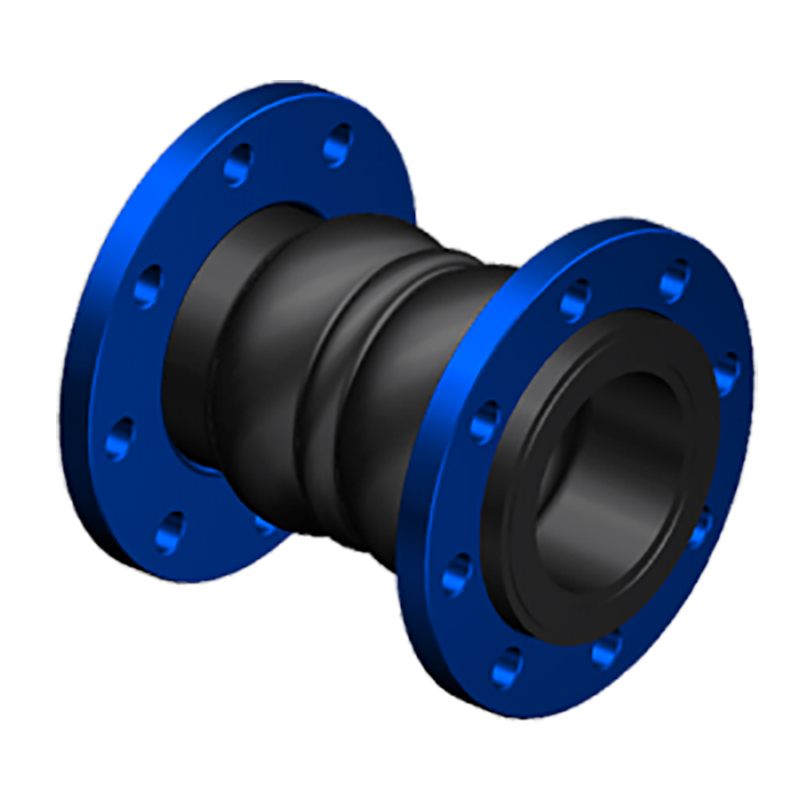

Hot New Products China Single Sphere Rubber Bellow Expansion Joint (compensator)

We support our purchasers with ideal high-quality merchandise and significant level company. Becoming the specialist manufacturer in this sector, we now have received loaded practical encounter in producing and managing for Hot New Products China Single Sphere Rubber Bellow Expansion Joint (compensator), If possible, remember to ship your requirements with a detailed list including the style/item and quantity you require. We’re going to then mail our best price ranges to you.

We support our purchasers with ideal high-quality merchandise and significant level company. Becoming the specialist manufacturer in this sector, we now have received loaded practical encounter in producing and managing for China Rubber Bellow, Flexible Rubber Joint, Our merchandise are mainly exported to Southeast Asia, the Middle East, North America and Europe. Our quality is surely guaranteed. If you are interested in any of our items or would like to discuss a custom order, make sure you feel free to contact us. We’ve been looking forward to forming successful business relationships with new clients around the world in the near future.

Details

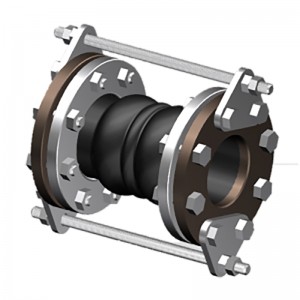

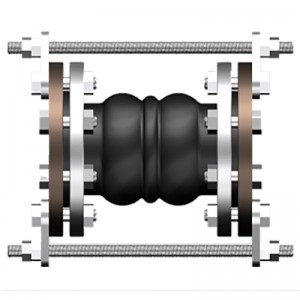

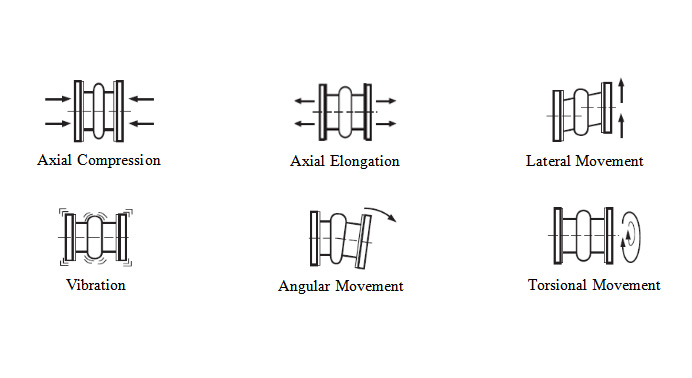

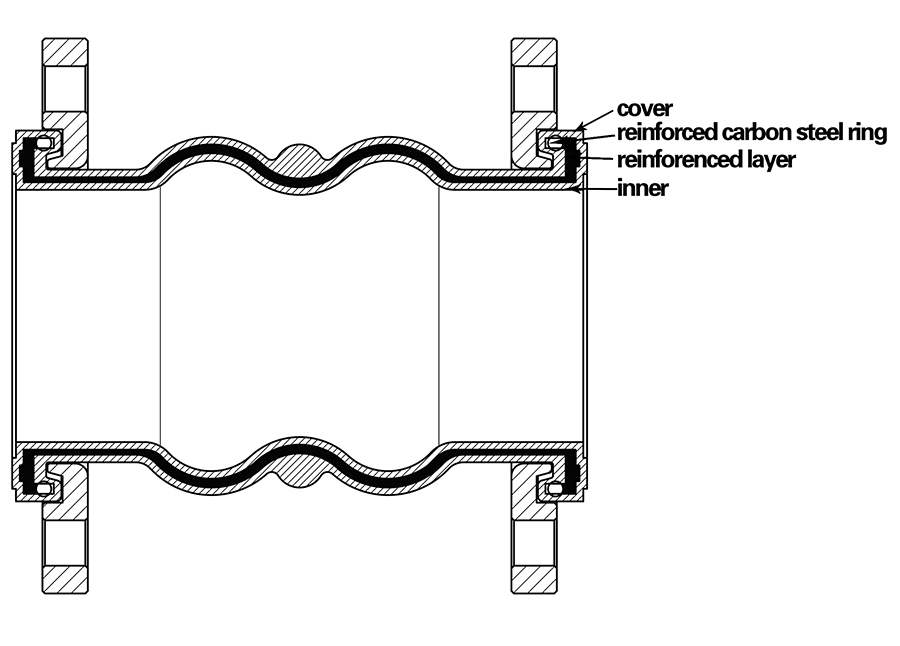

Double-arch products are used where more movement is needed. If the piping pressure is much higher, reinforced bolts should be assembled together with flanges. Reinforcement layer of the bellows by Nylon cords and at both ends by hardened steel wire rings. The floating steel flanges are drilled according to DIN, ANSI, BS, JIS and other standards.

| Specifications | I | II | III |

| Working Pressure Mpa (Kgf/Cm2) | 1Mpa (10) | 1.6 (16) | 2.5 (25) |

| Test Pressure | 1.5Mpa | 2.4Mpa | 3.75Mpa |

| Burst Pressure Mpa (Kgf/Cm2) | 3 (30) | 4.8 (48) | 5.5 (55) |

| Vacuum Kpa (Kgf/Cm2) | 53 (400) | 86(660) | 100 (750) |

| Materials | EPDM/NBR/SBR/NR | ||

| Diameter Range | DN15-DN600 (1/2″-24″) | ||

| Connection Method | FLANGETHREADCLAMP | ||

| Flanges Dimensions | DIN, EN,ANSI, BS, JIS and other standards | ||

| Applicable Medium | Air, compressed air, water, seawater, hot water, oil, acid, alkali etc. | ||

| Loading Port: | Qingdao, China | ||

| Shipment Terms: | FOB, CFR, CIF | ||

| Production Capacity: | 50000 set | ||

| Payment Terms: | L/C, T/T, D/P | ||

| Connection: | Flange, Thread | ||

| Flange Material: | Carbon Steel, Stainless Steel | ||

| Period of Delivery | about 21 working days | ||

|

Double Arch-Standard Length |

||||||||

|

Dimensions |

Movement Distance |

Operating Condition |

||||||

|

Pipe Size |

O’all Length |

Axial Compression |

Axial Extension |

Lateral Deflection |

Angular Deflection |

Max w.p. bar(psi) |

Max Vacuum in. of Hg(mm hg) |

|

|

Inch |

mm |

mm |

mm |

mm |

mm |

|||

|

1 1/4″ |

32 |

175 |

45 |

30 |

45 |

45° |

16(225) |

26(660) |

|

1 1/2″ |

40 |

175 |

45 |

30 |

45 |

45° |

16(225) |

26(660) |

|

2″ |

50 |

175 |

45 |

30 |

45 |

45° |

16(225) |

26(660) |

|

2 1/2″ |

65 |

175 |

45 |

30 |

45 |

45° |

16(225) |

26(660) |

|

3″ |

80 |

175 |

45 |

30 |

45 |

45° |

16(225) |

26(660) |

|

4″ |

100 |

225 |

50 |

35 |

40 |

30° |

16(225) |

26(660) |

|

5″ |

125 |

225 |

50 |

35 |

40 |

30° |

16(225) |

26(660) |

|

6″ |

150 |

225 |

50 |

35 |

40 |

30° |

16(225) |

26(660) |

|

8″ |

200 |

325 |

60 |

35 |

35 |

15° |

16(225) |

26(660) |

|

10″ |

250 |

325 |

60 |

35 |

35 |

15° |

16(225) |

26(660) |

|

12″ |

300 |

325 |

60 |

35 |

35 |

15° |

16(225) |

26(660) |

|

14″ |

350 |

350 |

60 |

35 |

35 |

15° |

10(150) |

26(660) |

|

16″ |

400 |

350 |

60 |

35 |

35 |

15° |

7(100) |

26(660) |

|

18″ |

450 |

350 |

70 |

65 |

50 |

10° |

7(100) |

16(400) |

|

20″ |

500 |

350 |

70 |

65 |

50 |

10° |

7(100) |

16(400) |

|

24″ |

600 |

350 |

70 |

65 |

50 |

10° |

7(100) |

16(400) |

|

Double Arch-American Standard |

||||||||

|

Dimensions |

Movement Distance |

Operating Condition |

||||||

|

Pipe Size |

O’all Length |

Axial Compression |

Axial Extension |

Lateral Deflection |

Angular Deflection |

Max w.p. (psi)-3,-4 |

Max Vacuum (in. of Hg)-5 |

|

|

Inch |

mm |

Inch |

Inch |

Inch |

Inch |

|||

|

1″ |

25 |

5″ |

2″ |

1.188″ |

±1.75″ |

45° |

225 |

26 |

|

1 1/4″ |

32 |

7″ |

2″ |

1.188″ |

±1.75″ |

45° |

225 |

26 |

|

1 1/2″ |

40 |

7″ |

2″ |

1.188″ |

±1.75″ |

45° |

225 |

26 |

|

2″ |

50 |

7″ |

2″ |

1.188″ |

±1.75″ |

45° |

225 |

26 |

|

2 1/2″ |

65 |

7″ |

2″ |

1.188″ |

±1.75″ |

43° |

225 |

26 |

|

3″ |

80 |

7″ |

2″ |

1.188″ |

±1.75″ |

38° |

225 |

26 |

|

4″ |

100 |

9″ |

2.25″ |

1.375″ |

±1.562″ |

34° |

225 |

26 |

|

5″ |

125 |

9″ |

2.25″ |

1.375″ |

±1.562″ |

29° |

225 |

26 |

|

6″ |

150 |

9″ |

2.25″ |

1.375″ |

±1.562″ |

25° |

225 |

26 |

|

8″ |

200 |

13″ |

2.5″ |

1.375″ |

±1.375″ |

19° |

225 |

26 |

|

10″ |

250 |

13″ |

2.5″ |

1.375″ |

±1.375″ |

15° |

225 |

26 |

|

12″ |

300 |

13″ |

2.5″ |

1.375″ |

±1.375″ |

13° |

225 |

26 |

|

14″ |

350 |

13.75″ |

1.75″ |

1.118″ |

±1.118″ |

9° |

150 |

26 |

|

16″ |

400 |

13.75″ |

1.75″ |

1.118″ |

±1.118″ |

8° |

150 |

26 |

|

18″ |

450 |

13.75″ |

1.75″ |

1.118″ |

±1.118″ |

7° |

150 |

26 |

|

20″ |

500 |

13.75″ |

1.75″ |

1.118″ |

±1.118″ |

7° |

150 |

26 |

|

24″ |

600 |

13.75″ |

1.75″ |

1.118″ |

±1.118″ |

5° |

150 |

26 |

|

Double Arch-Jis Standard |

||||||||

|

Dimensions |

Movement Distance |

Operating Condition |

||||||

|

Pipe Size |

O’all Length |

Axial Compression |

Axial Extension |

Lateral Deflection |

Angular Deflection |

Max w.p. bar(psi) |

Max Vacuum in. of Hg(mm hg) |

|

|

Inch |

mm |

mm |

mm |

mm |

mm |

|||

|

1 1/4 |

32 |

175 |

20 |

10 |

20 |

20° |

16(225) |

26(660) |

|

1 1/2 |

40 |

175 |

20 |

10 |

20 |

20° |

16(225) |

26(660) |

|

2 |

50 |

175 |

20 |

10 |

20 |

20° |

16(225) |

26(660) |

|

21/2 |

65 |

175 |

20 |

10 |

20 |

20° |

16(225) |

26(660) |

|

3 |

80 |

175 |

20 |

10 |

20 |

20° |

16(225) |

26(660) |

|

4 |

100 |

225 |

30 |

15 |

25 |

20° |

16(225) |

26(660) |

|

5 |

125 |

225 |

30 |

15 |

25 |

20° |

16(225) |

26(660) |

|

6 |

150 |

225 |

30 |

15 |

25 |

20° |

16(225) |

26(660) |

|

8 |

200 |

325 |

40 |

20 |

30 |

20° |

16(225) |

26(660) |

|

10 |

250 |

325 |

40 |

20 |

30 |

20° |

16(225) |

26(660) |

|

12 |

300 |

325 |

40 |

20 |

30 |

20° |

16(225) |

26(660) |

Products categories

-

Phone

-

E-mail

-

Whatsapp

whatsapp

-

WeChat

Jessy Lin

-

WeChat

Ellen Zhang